Business Leadership

With decades of experience as global energy and technology leaders, our executives are primed to manage fast-paced growth.

We are sharing our vision for Clean Energy. Everywhere. Forever.

THIS IS OUR MOMENT

We are pursuing the fastest, most practical path to bringing fusion energy to market using Magnetized Target Fusion (MTF) technology.

Today’s economic, social, and political trends increase the demand for fusion energy. We’re on track to deliver zero-carbon energy to the grid by the early to mid-2030s with our proprietary technology.

Join us as we seek to transform the world’s energy supply.

OUR GOAL

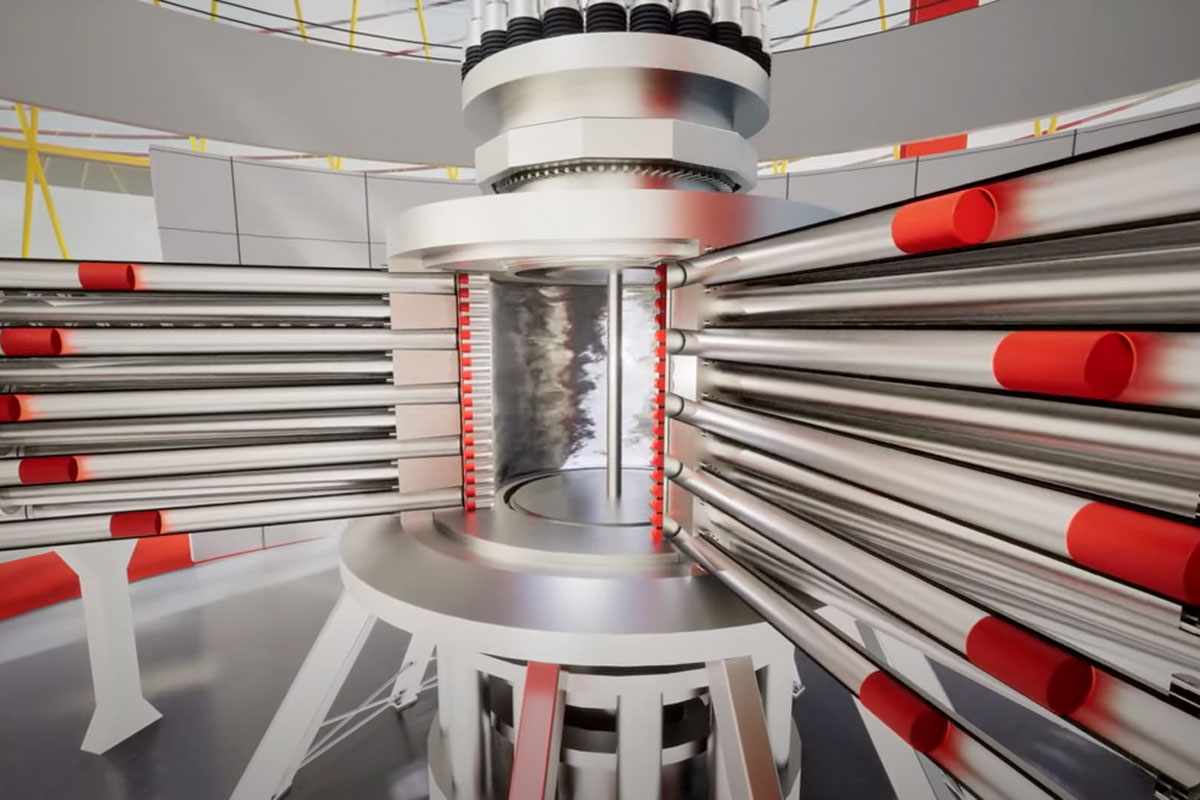

We are fast tracking our technical progress to provide commercial fusion energy to the grid by the 2030s by building a new MTF fusion machine in Richmond, British Columbia. Called Lawson Machine 26 – LM26 – the machine is designed to achieve fusion conditions of over 100 million degrees Celsius by 2025, with a goal of achieving breakeven by 2026.

ABOUT US

Two forces are shaping the future of energy. Demand for electricity is increasing while targets for carbon emission reductions are becoming more aggressive. We have put talent and technology together to supply affordable access to energy in concert with economic and social realities.

With decades of experience as global energy and technology leaders, our executives are primed to manage fast-paced growth.

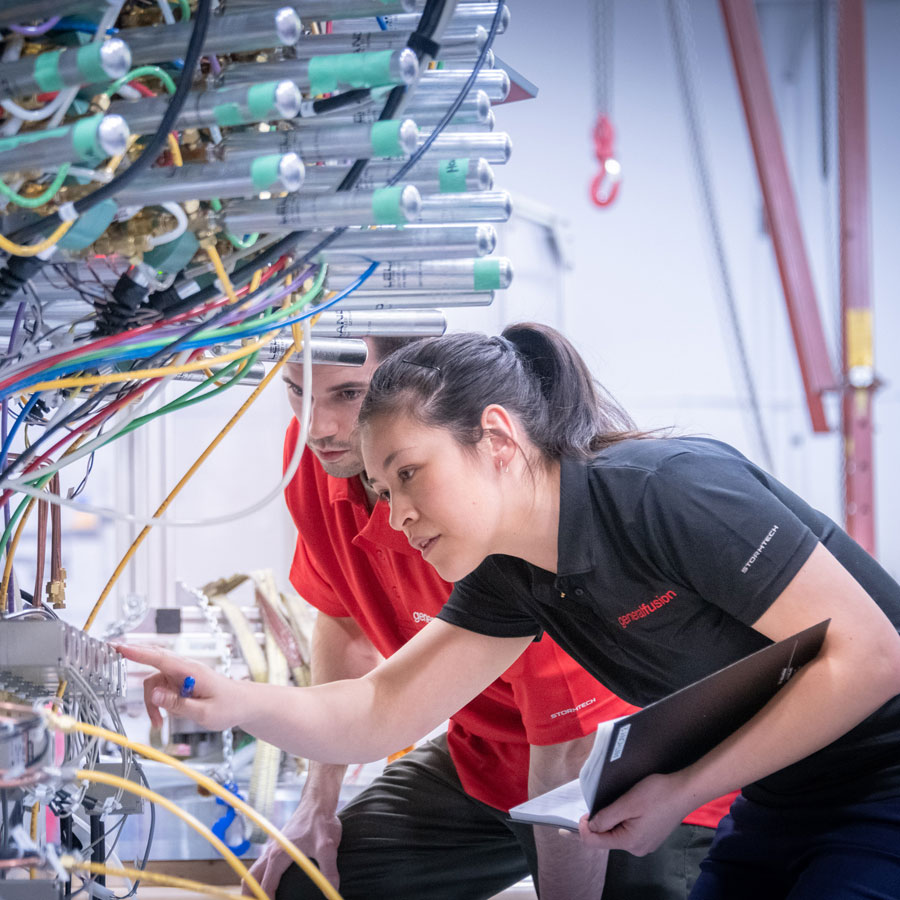

General Fusion’s multidisciplinary team has proven experience designing and building both fusion systems and power plants.

Increase in electricity demand by 2050.

Decrease in net CO₂ emissions targeted by 2050.

Per year potential fusion market opportunity.

This compelling opportunity resonated with our core ESG and cleantech-focused partners.

Why Fusion

Agile and reliable, fusion power is expected to make better use of land and offer energy independence to all countries, regardless of geography.

Fusion is on course to produce the electricity needed to power homes, businesses, and industry in the 2030s.

Resources

Explore our regular updates on General Fusion and fusion energy news.

Media Inquiries

The climate data is in. Urgent action is needed. Join us to make the change the world needs. At General Fusion, we’re making the future, creating power-plant-relevant scale fusion technology to transform how we energize the world — today.

Ready to take climate action?