Lawson Program

This program involves a machine already in operation, LM26, that is designed to create fusion conditions at 50% power plant scale and validate our approach with industry‑changing milestones.

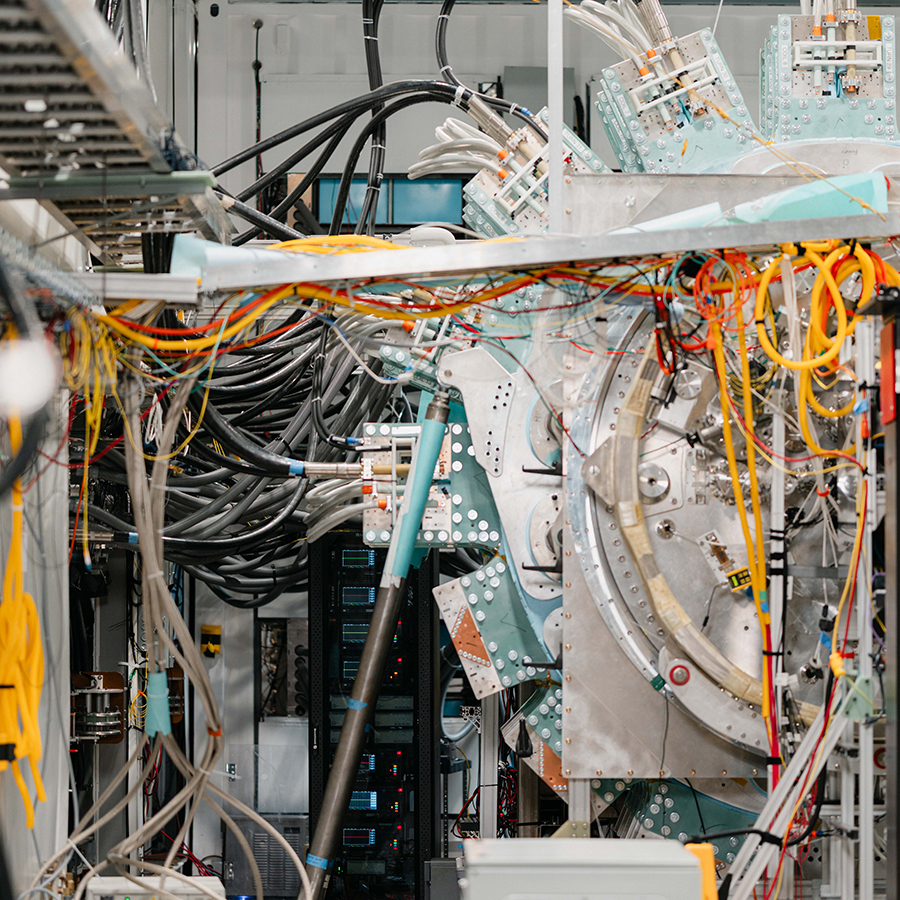

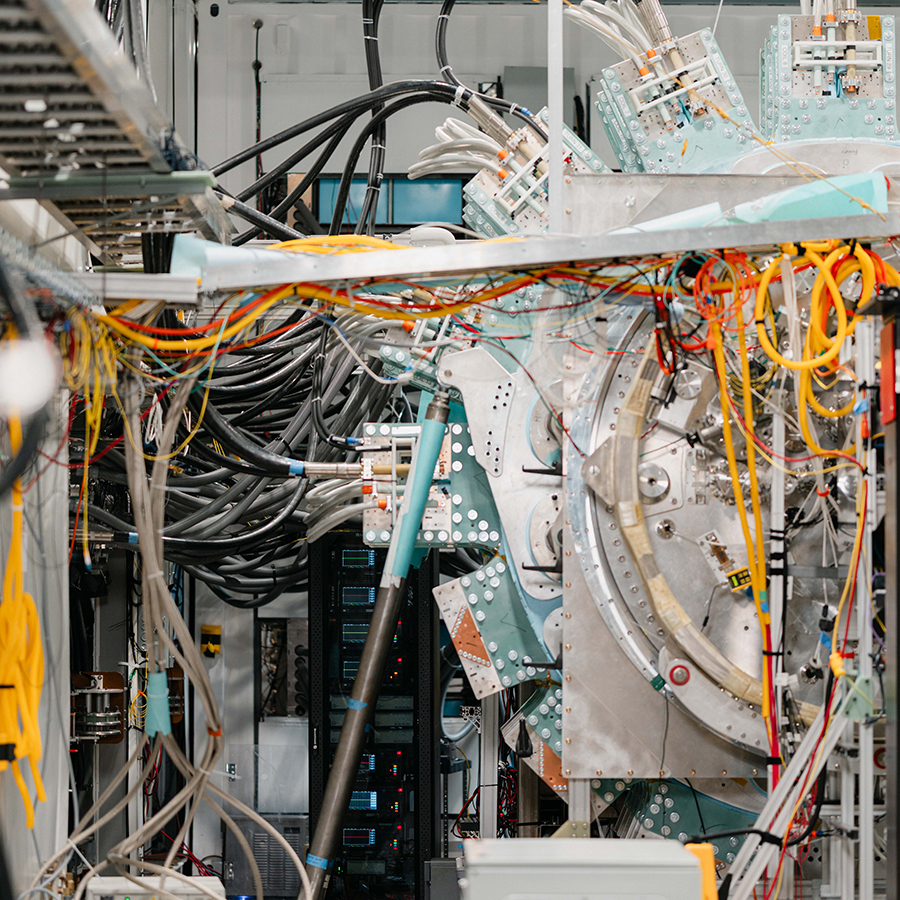

Today, General Fusion operates Lawson Machine 26 (LM26), a world‑first Magnetized Target Fusion (MTF) machine that was designed, built, and brought into operation in under two years. LM26 serves as the foundation for our program to achieve a series of transformative technical milestones that position us to deliver a first‑of‑a‑kind plant producing energy around 2035.

We aim to have the Lawson Program completed by mid‑2028. As we make progress with LM26, General Fusion intends to move into our commercialization program, an engineering program to design and demonstrate key commercial systems and components such as seals, valves, and heat‑exchange systems.

This leads to our goal of completing the final design of a first‑of‑a‑kind plant and beginning operations around 2035.

.

This program involves a machine already in operation, LM26, that is designed to create fusion conditions at 50% power plant scale and validate our approach with industry‑changing milestones.

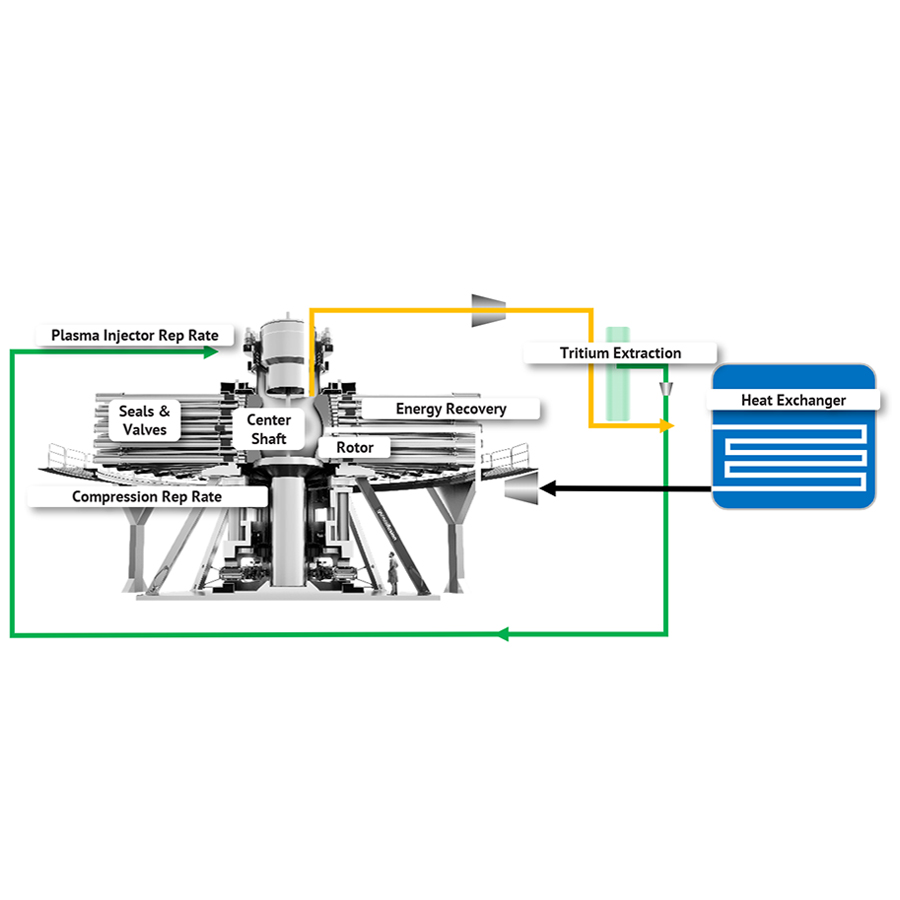

The goals of this program are to design and demonstrate key commercial systems and components, including seals and valves, liquid‑metal systems, and balance‑of‑plant and heat‑exchange systems.

A General Fusion FOAK plant will achieve engineering breakeven with an integrated commercial‑scale MTF machine, producing energy at commercial scale.

Collaborators and Suppliers

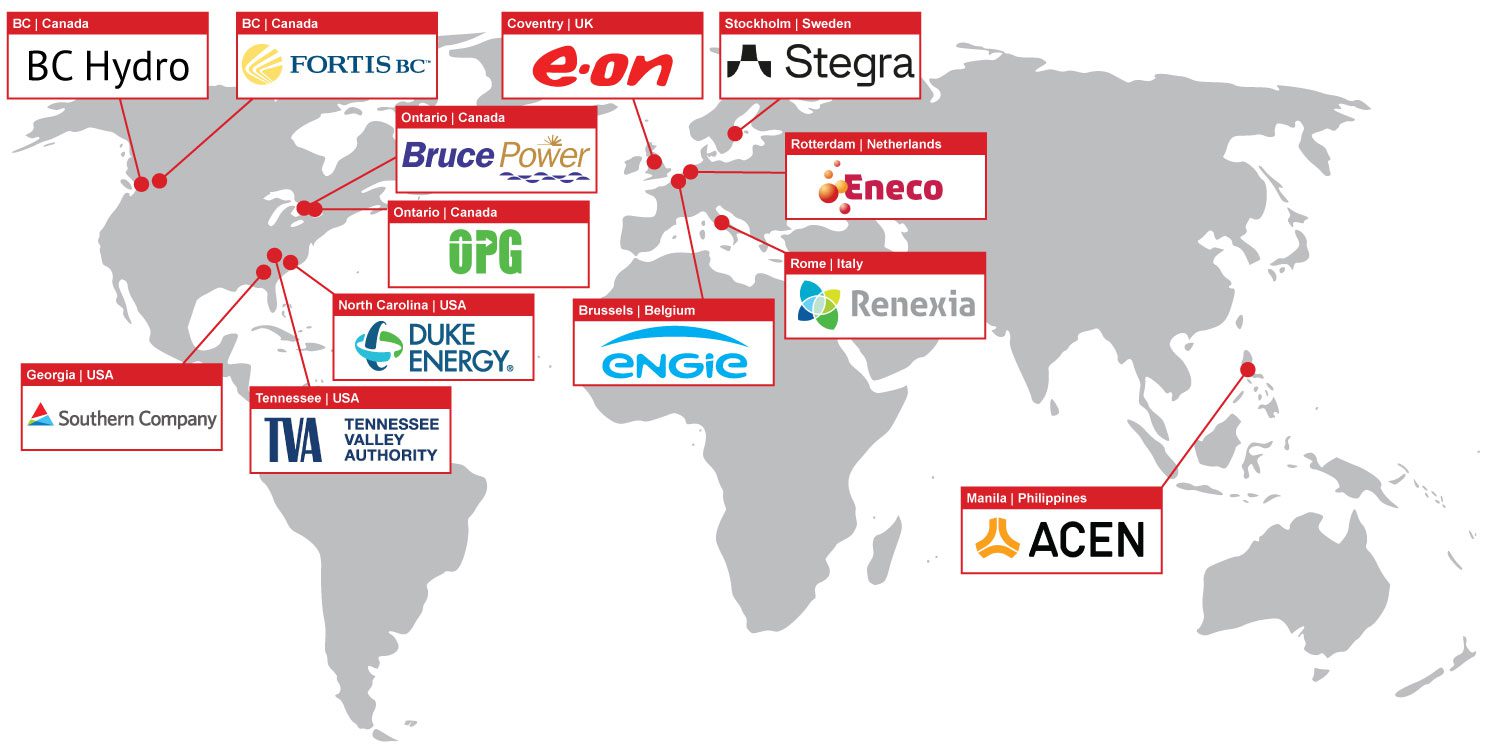

General Fusion’s pathway is validated by an ecosystem of collaborators, suppliers, and potential early adopters who are working with us today.

We work with a wide array of technical and commercialization partners, including the UK Atomic Energy Authority and the U.S. Department of Energy on R&D and technology development; commercial collaborators such as Hatch on power‑plant engineering; Kyoto Fusioneering on fuel‑cycle and liquid‑metal systems; and a major automaker on piston‑compression technology development.

We are also engaged with more than a dozen potential end users who have signed agreements to join our Market Development Advisory Committee and work with us on our technology development and commercialization efforts.

What sets General Fusion apart from the outset is our uniquely practical MTF approach with a liquid metal wall. Our technology was designed from the ground up with a power plant in mind.

By addressing key barriers such as material degradation, fuel production, energy capture, and cost, our approach offers a practical path without relying on expensive lasers or superconducting magnets.

The liquid metal wall: