By Dr. Michel Laberge, Founder & Chief Scientist, and Michael Delage, Chief Technology Officer at General Fusion.

General Fusion has focused a lot of effort on plasma technology over the past few years, and that investment is now paying off.

For those of you who don’t spend all day playing with plasma, here’s a quick reminder of what it is: plasma is the superheated gas that is the fuel for a fusion power plant. Controlling the behaviour of plasma is widely considered one of the most difficult aspects of fusion.

General Fusion is a leader in the development of plasma, specifically a type of plasma classified as “self-organizing”, and has set some world records along the way. Today we’re going to have a look at how this has been progressing.

If you’re not already familiar with how our system works, take a minute to watch the video below which covers the main points.

Most fusion machines use long plasma pulses and work to control the plasma with large magnets. The liquid metal wall that surrounds our plasma prevents us from doing the same, but the tradeoff is that the liquid metal provides major advantages for compression and energy capture which could make for a more commercially viable machine.

Rather than controlling the plasma in this environment with external magnets, General Fusion uses shorter plasma pulses that don’t have to be actively controlled – once the plasma is formed into the compression chamber it is on its own, unsupported.

The plasma then only needs to hold its structure for long enough to be compressed to fusion temperatures, which takes place in 1/100th the time it takes to blink. Plasma is the same stuff that lightning is made from, and moves on a very different timescale to you and I. The fractions of a second involved may not seem like much, but even this is a long time for a hot, dense fusion plasma.

In fact, trying to make a plasma that has the right temperature, density and magnetic characteristics has been one of the big challenges we’ve faced in our pursuit of fusion. Since we built our first large plasma injector in 2010, we’ve developed 18 generations of machines, progressively improving the designs to the point they are at today.

To give you an idea of progress, the original small plasma injectors we built in 2012 were achieving plasma lifespans on the order of 40 microseconds. Jump to 2018 and our latest generation of these injectors (called “SPECTOR”) are producing plasma pulses lasting up to 3,300 microseconds. As far as we know, that’s a world record for a plasma of its type and size.

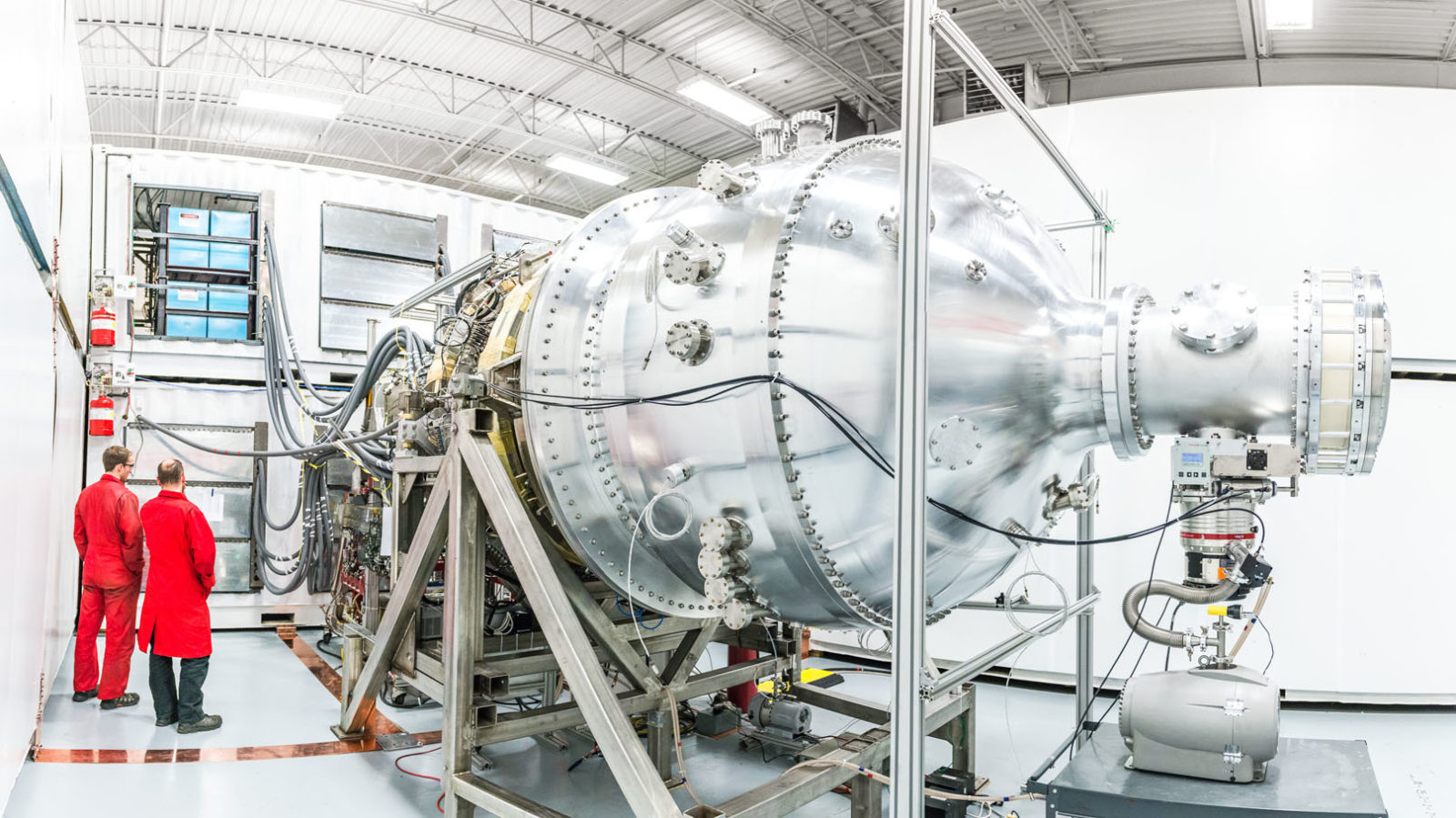

This is in a machine with a plasma chamber the size of a microwave. Our new machine, PI3, takes this design and scales the plasma chamber up to the size of a small car. Plasma works better when it is bigger, therefore we’re expecting that these plasma pulses will last at least ten times longer than the ones in the small SPECTOR injectors.

That means they will last long enough to compress, so the next step is to combine these plasma systems with our compression systems in a fusion demonstration plant.

You might be wondering how we compress plasma faster than the blink of an eye – we’ll cover this in our next newsletter where we’ll talk about compression systems and the cutting edge electronics that make this possible.

In the meantime, you can find more details about our plasma research program in our research library.

This article first appeared in the June 2018 edition of General Fusion’s quarterly Matters of State newsletter. Subscribe here to receive the next edition.