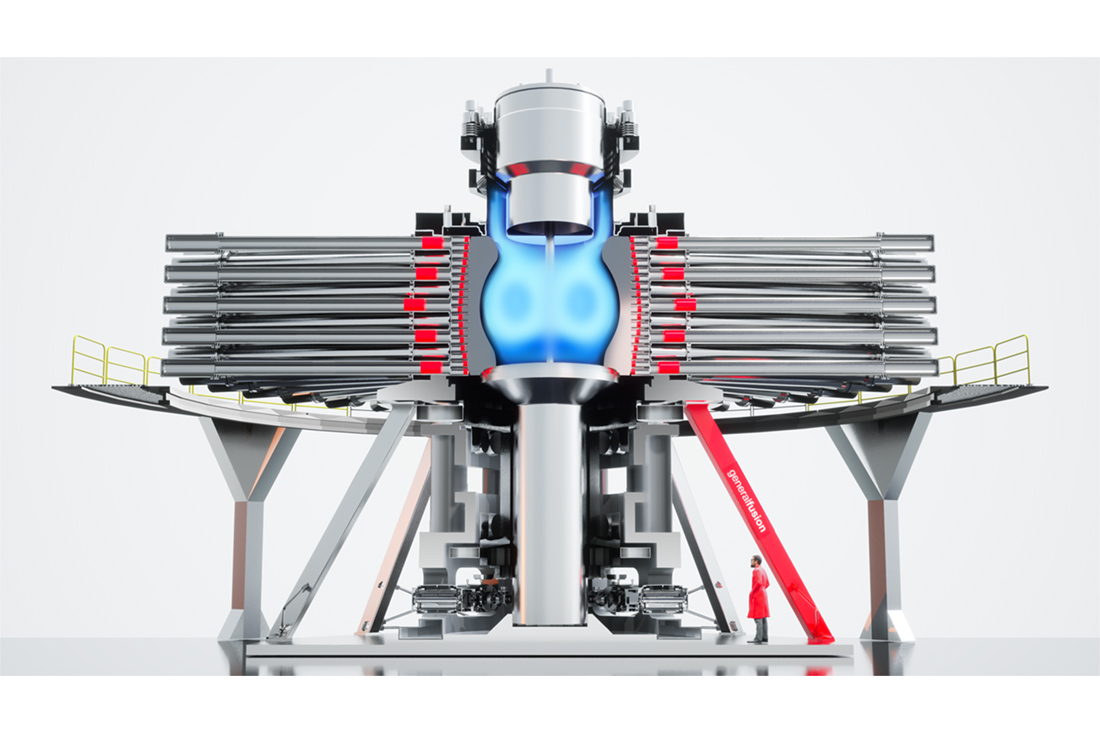

General Fusion is building a first-of-a-kind Fusion Demonstration Plant (FDP) to showcase our Magnetized Target Fusion (MTF) technology. Hosted by the UK Atomic Energy Authority at its Culham Campus – a world-leading fusion research hub – the FDP will be the largest privately funded MTF prototype in history. Construction is scheduled to begin in 2022, with operations starting in 2025.

Why MTF?

We take a practical approach to fusion energy, maximizing the use of existing industrial technologies, such as pneumatic pistons. In addition, our technology does not rely on large, superconducting magnets or expensive lasers. As a result, the supply chain is more readily available, making it easier to manufacture and scale than other fusion technologies – meaning a shorter timeline to powering homes, businesses, and industry with fusion energy.

What makes up our MTF device?

The FDP is the result of over a decade of development; it assembles proven components into a scaled version of our commercial machine.

The device consists of three key components:

- Compression system

- Liquid metal chamber

- Plasma injector

What will the FDP do?

The role of the FDP is to prove the viability of our MTF technology so we can scale it to a commercial pilot plant. To do this, we will create fusion conditions in a power-plant relevant environment without producing power. The FDP will create neutrons, and the data it creates will provide the information we need to build a commercial pilot plant that generates electricity.

How will the FDP set the scene for a commercial pilot plant?

The FDP is built to a 70 per cent scale of the commercial pilot plant

- At this scale, the FDP will be closer to a power generation plant than any other fusion energy prototype. We will demonstrate the economics and technology required to manufacture and operate a full-scale power plant.

The FDP and commercial pilot plant will reach plasma temperatures of more than 100 million degrees Celsius

- Reaching fusion temperatures allows us to demonstrate the key performance of the prototype using an approach that is extendable to a power plant.

The FDP will cycle one plasma pulse per day, where the commercial pilot plant will eventually cycle up to every second

- By completing one cycle per day, we can analyze the cycles and optimize our fusion process. Once this is perfected, the frequency can be increased to up to one cycle per second in the commercial facility.

The FDP will use deuterium fuel, where the commercial pilot plant will use a deuterium-tritium mix

- Using deuterium significantly simplifies the design while still providing the necessary data required.

What’s next?

With the data gathered from the FDP, we will be ready to design and build a first-of-a-kind commercial pilot plant. Our goal is to bring zero-carbon fusion energy to the world by the early 2030s.