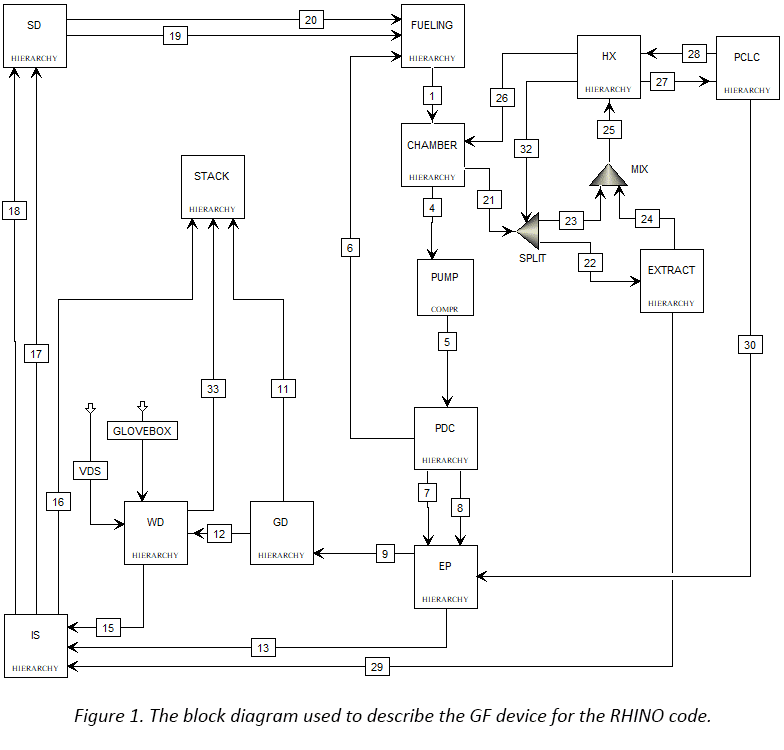

Executive Summary

This report describes the results from an INFUSE research project, where Savannah River National Laboratory (SRNL) in collaboration with General Fusion (GF) used process modeling to understand and optimize commercial power plant (CPP) fuel cycle designs based on parameters provided by GF. The study primarily focused on two candidate fuel cycles with different blanket materials, one with a lead lithium eutectic (LLE) blanket and the other with a pure lithium (Li) blanket. LLE benefits from a low melting point, favorable neutronics, and lower reactivity, but liquid lithium has the potential for higher tritium breeding ratios (TBR) and does not poison the plasma as a high Z contaminant.

It was found that the main differences between LLE and Li designs are the extraction technologies required to remove tritium from the blanket and the amount of tritium and its distribution within the facility. More than 80% of the in-process tritium inventory for the LLE design is contained in the isotope separation system, while for the Li design, over 60% of the in-process tritium inventory is contained within the blanket material. This is due to significant tritium retention by Li. For the Li blanket, the burden of tritium processing rests on the blanket extraction technology rather than the traditional exhaust processing route. Thus, the blanket extraction technology is a main driver of tritium inventory in the Li system and determines the subsequent interface with the tritium processing plant.