The race is on to produce commercial fusion energy, and General Fusion’s proprietary technology was built from the ground up with a power plant in mind. Our two decades of technology development have paved the way—we’re on track to provide energy to the grid by the early to mid-2030s. In our current design, a Magnetized Target Fusion (MTF) power plant would produce about 300 MWe from two 150 MW machines running in tandem and provide cost-competitive, zero-carbon power to about 150,000 homes.

To commercialize our technology, we’re fast-tracking results with our LM26 program, designed to achieve transformational milestones: fusion conditions of over 100 million degrees Celsius (10 keV) by 2025 and scientific breakeven equivalent by 2026.

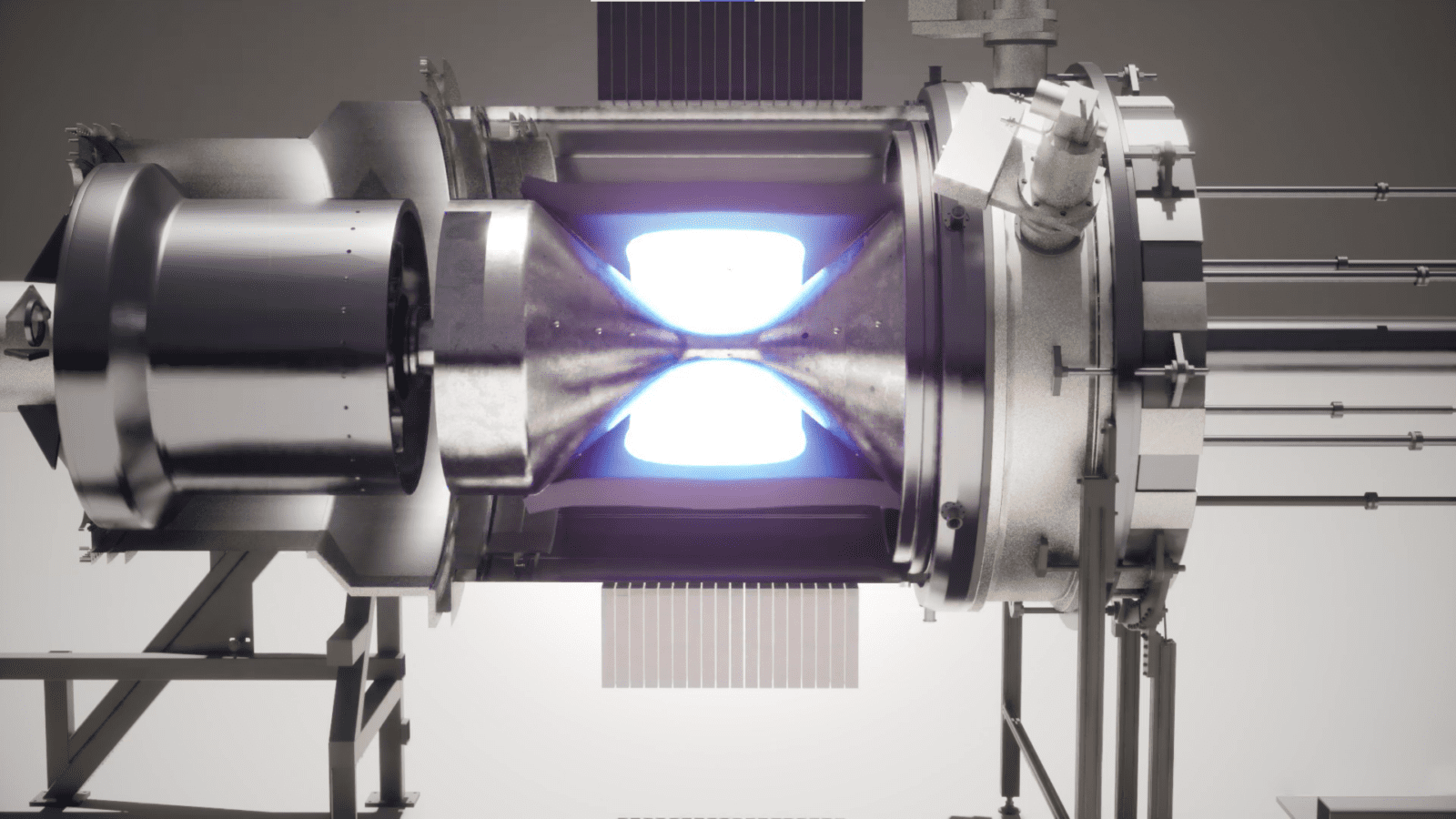

Watch: LM26 will magnetically compress our plasmas using a solid lithium liner.

LM26’s plasmas will be formed by our world-class plasma injector, PI3, and compressed with a solid lithium liner. A state-of-the-art diagnostics system in the centre shaft of the machine will provide thousands of data points, analyzing the plasma performance with each run.

We launched the LM26 program in August 2023 and provided an update in January 2024. Here’s what we’ve been up to since then.

Progressing P0

Launched in the Fall of 2023, our P0 testbed uses magnetic force to compress a solid lithium tube. It’s a small-scale version of the LM26 compression system and provides critical data, significantly de-risking LM26.

Since January, the team has set an operating rhythm, conducting weekly compression experiments and completing over 30 tests so far.

In this time, we’ve amped up our experiments—literally! The machine has successfully reached its maximum operations for shaft current, liner temperature, and compression capacitor bank energy. This means it is operating the way we expect, and we’re on track to scale up to the next machine.

Most importantly, the team dramatically improved the quality of the solid lithium liners. These custom liners are made in-house and machined on our lathe under an inert atmosphere. We target smooth, uniform, solid liners to achieve symmetry during compression.

“With every shot, we hone our approach. It’s been exciting to watch everything come together so rapidly. Now, our solid lithium liners are compressing in a much more symmetrical, smooth manner.”

— Kelly Epp, LM26 Project Manager

Additionally, we’ve set up a full suite of diagnostics to analyze each liner compression. The new data and measurements allowed us to validate our models. Our simulations match up well with our experimental results.

“Aligning the simulations with our physical results gives us the confidence we need to progress to the next step – building the full-scale compression device for LM26,” added Kelly.

Our team creates a solid lithium liner for a P0 compression test.

Powering up for LM26

PI3 is General Fusion’s operational plasma injector. Commissioned in 2017, it has already created plasmas with energy confinement times of approximately 10 milliseconds – the duration required to compress them to fusion conditions. Now, PI3 is getting levelled up to serve as LM26’s plasma injector.

To achieve 10 keV, LM26 will need more power, and our team of renowned pulse power experts is ready to ramp it up. We use capacitor banks to store energy like batteries. When we form a plasma, the energy stored in the capacitor banks is released quickly like a bolt of lightning. To power up for LM26, we received 18 capacitor banks and are completing rigorous testing on each one. This will provide 18 MJ of cap bank energy to drive LM26’s compression system!

More power! Capacitor banks arrive at our Richmond headquarters.

Data will drive the LM26 program. A comprehensive suite of diagnostics and integrated modelling will help us optimize the machine’s performance. Data will also confirm when we hit our target milestones.

In May, Lawrence Livermore National Laboratory—renowned for achieving fusion ignition in 2022—published simulation models with their unique code using data from PI3 to predict plasma edge behaviour. This work helps us better predict how our plasma will behave when compressed to fusion conditions in LM26.

Additionally, the team progressed several diagnostics to measure the temperature and density of our plasmas because accurately assessing 100-million-degree Celsius plasmas requires specialized equipment!

“We’ve teamed up with experts around the world to create a cutting-edge suite of diagnostics. Leaning on their expertise allows us to keep our rapid pace of development as we do what we do best: nimbly iterate to achieve first-of-a-kind milestones.”

— Mike Donaldson, Senior Vice President, Technology Development

Thomson scattering polychromators use scattered light to provide highly detailed temperature and plasma density profile measurements. These arrived from the UK Atomic Energy Authority earlier this year and are already providing valuable information to the team.

We’re also pushing the boundaries of science and innovation in our collaboration with TRIUMF, Canada’s particle accelerator centre. Together, we’re advancing a diagnostic system that will tag neutron interactions every nanosecond! This enables us to precisely measure neutron energies at a very high rate. The sophisticated spectrometer will measure ion temperature, a critical plasma parameter, at peak compression of a magnetized plasma. It’s another tool in our toolbelt to measure plasma temperatures at fusion conditions.

MTF momentum: designing a power plant

LM26 is designed to achieve monumental milestones. Simultaneously, we continue to advance the design of our commercial machine. A key component is our liquid metal compression system. Our primary liquid compression testbed has completed over 1,000 experiments. Its peer-reviewed results, published earlier this year in Fusion Engineering and Design, validate that we can produce the smooth, rapid, and symmetrical compression of a liquid cavity needed for an MTF power plant.

Our primary liquid compression testbed has completed over 1,000 experiments.

A look inside: A smooth, shaped collapse of a liquid wall is demonstrated during an experiment.

We’ve also made breakthroughs in modelling the liquid metal liner in a commercial machine by developing a proprietary code introduced in the March issue of Physics of Fluids. No other programming available on the market can achieve its rapid results, enabling us to quickly test different designs and configurations for a power plant. This is yet another example of our physical testbeds and simulations working together to advance our technology, providing the confidence needed to advance to the next step.

Every decision we make at General Fusion is driven by the need for MTF to practically scale for commercial applications. That’s why we also work with experts in power plant design, licensing, and operations to make sure our approach will fit users’ needs. In April of this year, we announced a new project with Canadian Nuclear Laboratories (CNL) to identify the most efficient and cost-effective designs to integrate our fusion machine, balance of plant, and power conversion systems into a power plant. The collaboration leverages CNL’s expertise in reactor design and tritium R&D. Strategic partnerships such as this are imperative as we advance our technology to power a fusion future by the early to mid-2030s—and fundamentally transform the energy sector forever.

“Our eye is on the prize: generating abundant, clean, and cost-competitive fusion energy with MTF. We’re not here for a science project; we’re making tangible progress towards commercialization every single day. I’m proud to be a part of this outstanding team.”

— Megan Wilson, Chief Strategy Officer