Experiments are an important step in merging components for a Fusion Demonstration Plant

By Michael Delage, Chief Technology Officer at General Fusion

General Fusion’s design for its Fusion Demonstration Plant calls for forming a magnetized plasma in a cavity of molten lithium, and then rapidly collapsing the cavity to compress the plasma to fusion conditions. Over the years, the technologies for the plasma injection and liquid metal compression have been developed independently. They need to come together, and General Fusion is taking the first step by combining its successful SPECTOR (Spherical Compact Toroid) plasma injectors with a molten lithium system in a new device called SLiC (SPECTOR with Lithium). SLiC is designed to form magnetized plasmas in a target chamber where part of the target chamber’s wall is made up of molten lithium. The SLiC program will not only help us demonstrate that we can achieve plasma performance as good, or better, than achieved on a normal SPECTOR plasma injector, but also serve as a test bed for developing diagnostics compatible with molten lithium and provide data for the development of simulation codes to model the interaction of plasma magnetic fields with a free surface of liquid metal.

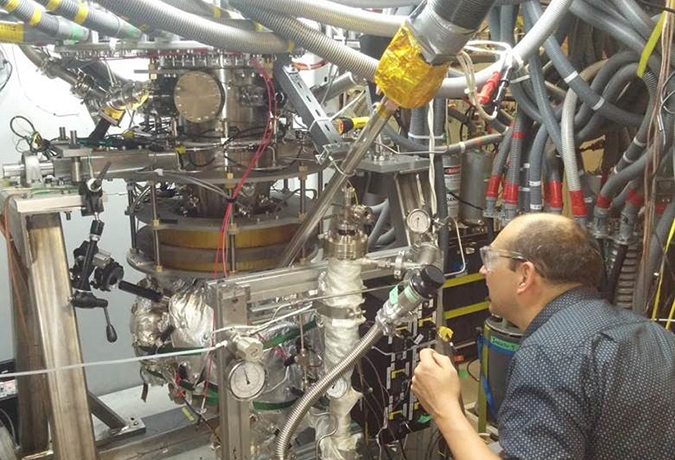

SLiC is a version of General Fusion’s smaller SPECTOR plasma injectors, turned upside down so that the plasma target chamber is below the injector. The target chamber is also redesigned so that it can be heated to over 300 °C and a molten lithium can be introduced. Starting with a simple configuration, the first phase of testing will have a puddle of lithium at the bottom of the injector. A second stage of the program will have molten lithium flowing down from the equator of the target chamber to the bottom so that plasmas are formed into a target chamber with ~40% of the surface covered by molten lithium. The upper half of the target chamber has ports for diagnostics such as magnetic probes, interferometry, spectroscopy, and fast video imaging.

As you might imagine, operating a system of this type is not without its challenges. Lithium is particularly reactive, and therefore materials need to be selected very carefully. The aluminum used for standard SPECTOR target chambers, for example, is incompatible with molten lithium. Instead, a special stainless steel-lined copper target chamber is needed. Once the lithium is in the system, the contact points between the molten lithium and solid components need to be able to carry hundreds of kiloamps of electric current without arcing or spraying lithium into the plasma – this requires careful understanding of how lithium wets solid surfaces and control of impurities in the lithium. Finally, the pulse of current creates magnetic fields that are strong enough to push the lithium metal around. During its millisecond life, the plasma doesn’t move much, but it can slosh around in the plasma injector coating things it shouldn’t (like electrical insulators). These risks were enough of a concern that General Fusion first built and tested a small system “mini-SliC” to address them.

SliC was put together in March and is now making plasmas. The testing program is well underway, and the system is already proving its usefulness for modeling and simulation benchmarking. The plasmas created in SliC have similarities to those in SPECTOR, and differences the team is currently investigating. SliC is proving to be the exact type of the test bed General Fusion needs, and we’ll keep you up-to-date on what’s next with this new machine.