Our plasma injector is ready. We’ve integrated the compression system. The fusion vessel is installed. After a busy few months and an incredible effort by our team, the Lawson Machine 26 (LM26) assembly is complete!

“This world-first machine embodies over two decades of breakthroughs in our practical Magnetized Target Fusion technology. With LM26, we are writing a new chapter in fusion innovation, and we’re set to kick off our most transformative year yet with first plasma in early 2025. From there, we will progress towards the major technical milestones of over 10 million degrees Celsius, 100 million degrees Celsius, and most importantly, scientific breakeven equivalent. With each step we get closer to our mission of fundamentally transforming the global energy system with MTF – providing clean energy, everywhere, forever.” — Greg Twinney, Chief Executive Officer

We provided progress updates in January and June. Now, we’re preparing for operations by beginning the “bake out” process (heating the machine under vacuum), installing the first suite of diagnostics and connecting the pulse power control systems. There’s lots on the go, check out what we’ve been up to lately!

- Integrating our plasma injector and compression system to assemble LM26

- Procuring, assembling, and testing the machine’s components

- Publishing our world-first plasma compression results that demonstrate MTF

- Advancing diagnostic technology to measure LM26’s transformative milestones

- Preparing for our biggest year yet in 2025!

Watch: LM26 takes shape in our Richmond facility

Procuring, assembling, and testing all the components

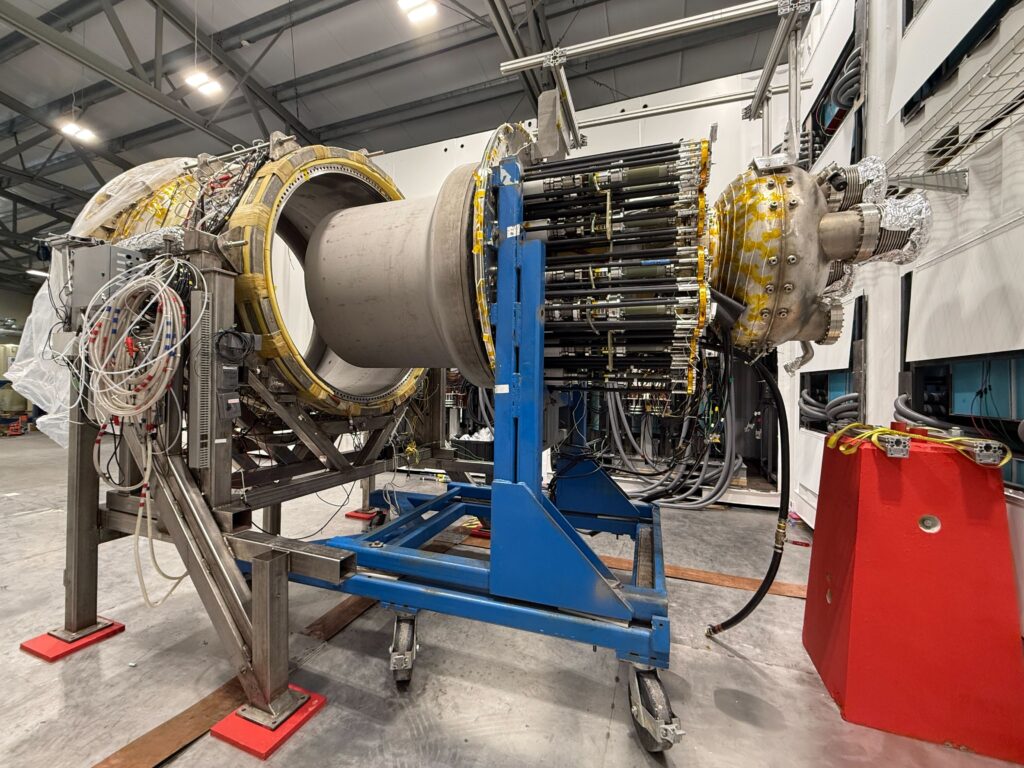

LM26 will use magnetic force to drive a lithium liner inward, compressing the plasma and heating it to key temperature thresholds for fusion, all in about five milliseconds. To prepare for the full-scale machine, our team created Prototype 0 (P0) — a small-scale version of the LM26 compression system. In August, we hit a milestone with P0’s 40th run, achieving positive results and providing the critical data we needed to scale up.

P0 was a critical compression testbed that came online shortly after our LM26 fusion demonstration program launched in August 2023

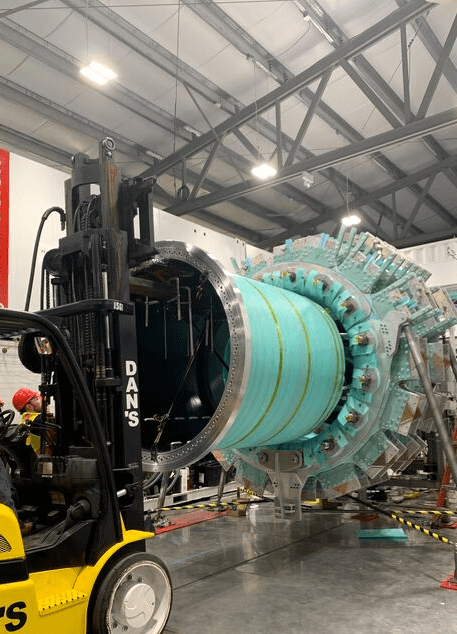

Next, our team quickly built and tested the compression coils for LM26. More than 70 plates for the coils were machined and assembled in-house. Now complete, the coils are two meters in diameter and weigh 11,000 kilograms. The coils will run 18 megajoules of high electrical current to magnetically compress our world-leading plasmas with the energy required to reach fusion conditions.

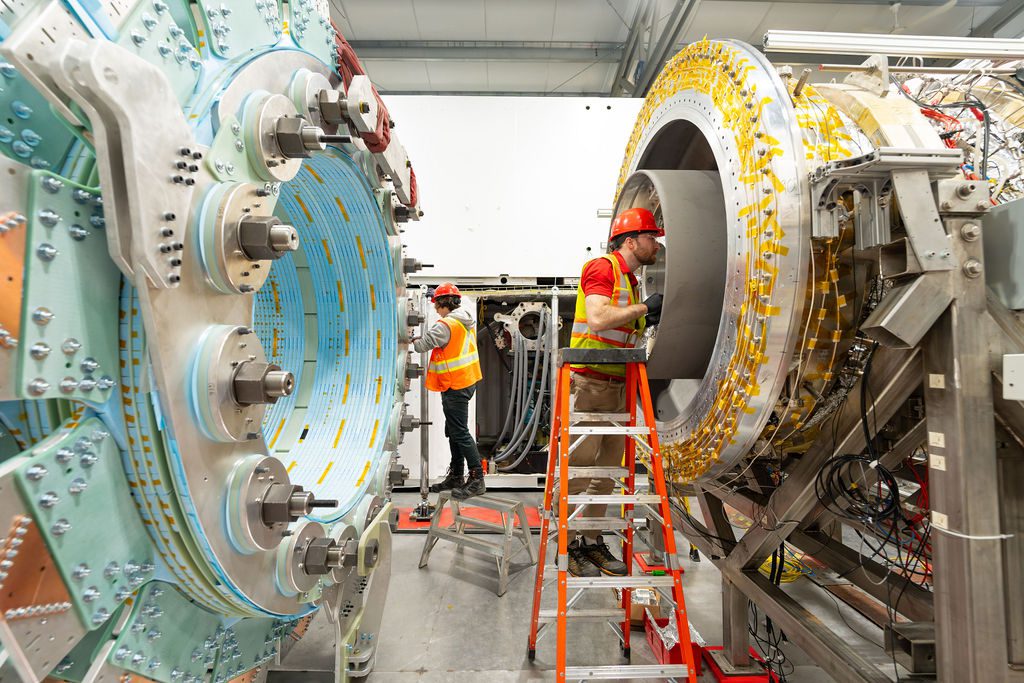

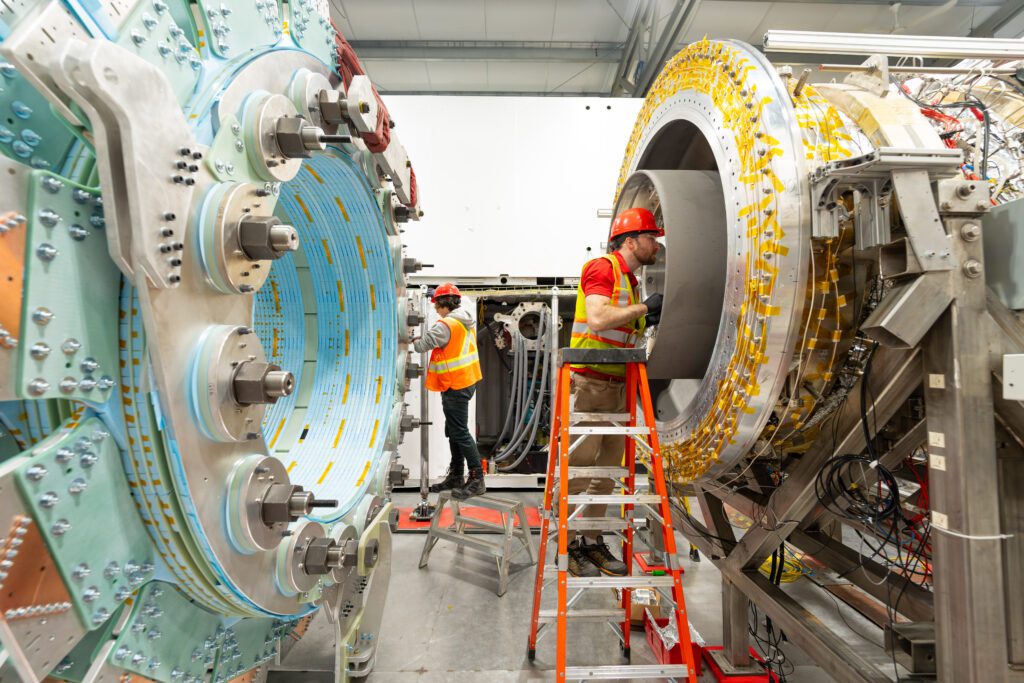

For LM26, we’ve integrated our plasma injector with a compression system. The machine will begin compressing plasmas at large scale in early 2025.

For LM26, we’ve integrated our plasma injector with a compression system. The machine will begin compressing plasmas at large scale in early 2025.

We also powered up in a big way for LM26, with 32 megajoules of pulsed power tested and ready to go! Pulsed power stores accumulated energy over time and discharges it rapidly for instantaneous power (like a lightning bolt)— an area we are experts in!

Our MTF approach uses pulsed power in many different applications:

- Ionizing the target gas to become a plasma

- Forcing the plasma into the target chamber of the plasma injector

- Generating the stabilizing magnetic field that helps keep our plasma confined

- Compressing the plasma via a conducting metal lithium liner

The fusion vessel – a core component of LM26 that houses the lithium liner that will compress plasmas in the machine – was prepped with coating, flanges were mounted, and copper conductors were added.

During the final stages of the LM26 assembly, the fusion vessel was installed inside the compression system

Another core component of LM26 – our plasma injector – was moved into place for integration with the compression system. This was an opportunity to thoroughly inspect and clean the machine’s flange, O-ring, and inner and outer electrodes to ensure it will maintain a high vacuum during LM26 operations.

“Our plasma injector has been operating since 2017, so when we opened it up to prepare it for LM26, we were happy to find no surprises! The inside of the machine was in great condition, and we were able to clean and reassemble it quickly. Now it’s ready for first plasma in LM26.” — Jeremy Pratt, Engineering Technician

In LM26, the inner electrode in our plasma injector is nested inside the outer electrode, and the gap between the two is where our plasmas are formed. The high-voltage breakdown between the two electrodes is what ionizes the gas we puff in, turning the gas into a plasma.

In LM26, the inner electrode in our plasma injector is nested inside the outer electrode, and the gap between the two is where our plasmas are formed. The high-voltage breakdown between the two electrodes is what ionizes the gas we puff in, turning the gas into a plasma.

The systems for creating LM26’s lithium liners also progressed quickly. Our supplier, Universe Machine, in Edmonton, Alberta, fabricated the parts for the custom die caster we are building to form the liners. Each liner for LM26 will be cast on-site at our facility using a process similar to the one we designed for P0.

The custom die caster, which will form LM26’s lithium liner, is fabricated here in Canada

Building on a solid foundation of peer-reviewed plasma compression research

Our world-first achievements in plasma compression were recently published in the scientific journal Nuclear Fusion. These peer-reviewed results underpin and derisk LM26, giving us confidence in the milestones we’re targeting when compressing plasmas at large scale to reach higher fusion yields. The experiment results verify the feasibility of our technology, showing that neutron yield increases when plasma is mechanically compressed – that significant volumetric compression of a spherical tokamak plasma is practical.

Key results from the experiment include:

- Neutron yield increased significantly, exceeding 600 million neutrons per second in one compression shot.

- During compression, the plasma became approximately 190 times denser than it started, consistent with plasma particle confinement time being significantly longer than the compression time.

- The magnetic field that provides robust confinement for the hot plasma became over 13 times higher than it started due to the action of compression.

- Measurements of plasma heating agreed well with the rate expected for the scale of the experiment, with a modest rise in ion temperature to approximately 0.63 keV during the compression.

Results published in Nuclear Fusion verify that during our Plasma Compression Science (PCS) experiment series, which ran from 2013 to 2019, we successfully produced significant fusion neutron yield by compressing plasmas in the spherical tokamak configuration required for our MTF approach.

Results published in Nuclear Fusion verify that during our Plasma Compression Science (PCS) experiment series, which ran from 2013 to 2019, we successfully produced significant fusion neutron yield by compressing plasmas in the spherical tokamak configuration required for our MTF approach.

Measuring success with experts around the world

A key area of our R&D collaboration program for LM26 is advancing cutting-edge diagnostic technology to precisely measure the performance of the machine. These diagnostics will provide the data we need to verify our results through third-party expert validation and peer-reviewed publication. Today, we’re working with the UK Atomic Energy Authority (UKAEA), TRIUMF, Simon Fraser University (SFU), and others to develop a robust system for LM26 spanning magnetic sensors, neutron detectors, spectroscopy, and laser-based diagnostics. In development are state-of-the-art Thomson scattering, interferometer, neutron spectrometer, and other critical devices. With funding from Innovate BC, we’ve also teamed up with B.C.’s Motus Design Group to develop a first-of-a-kind network cable to fibre optic media converter that will enable us to quickly install diagnostics on LM26 and support the extraction and storage of data. When operational, the diagnostics system will provide extensive data used to improve the capabilities of the machine with each run.

When LM26 begins compressing plasmas early in the new year, we’ll measure ion temperature from neutron counting, neutron yield, electron temperature from absolute extreme ultraviolet (AXUV) diodes, electron density from interferometers, plasma stability from magnetic probes, liner collapse symmetry with lasers and high-speed cameras, and ion temperature from an ion Doppler spectrometer. These measurements will verify the machine’s initial performance and plasma heating to our 10+ million degrees Celsius milestone.

Also in development is a state-of-the-art Thomson scattering system with Bertin Technologies and an ultra-fast neutron spectrometer with TRIUMF, SFU, and Université de Sherbrooke. The complete diagnostics plan for LM26 was presented at ITER during the ITPA 46th Topical Group on Diagnostics in October and was well-received by our industry peers.

“LM26’s diagnostics focus on measuring the key plasma parameters for the technical goals of our fusion demonstration program. We’ve developed a robust, reliable measurement strategy that’s received positive feedback from reviews with world-leading experts.” — Filiberto Braglia, Data Scientist and Lead Project Engineer for the LM26 diagnostic system

Twenty years of progress paved the way

As we look forward to the milestones planned for 2025, we’re reflecting on how far we’ve come. Groundbreaking energy technology isn’t created on a computer – you have to build it. And at General Fusion, we’re really good at building stuff. Over 20 years, we’ve advanced our technology from a garage to a state-of-the-art fusion campus with 140 talented employees shaping the future of energy in Canada with:

- Over two dozen prototypes

- 200,000+ plasma shots

- 1,000+ compression experiments

- World-first achievements in plasma compression, including increased neutron yield exceeding 600 million neutrons per second in one plasma compression shot

- The plasmas we need with 10-millisecond energy confinement times – the duration required to compress plasma to fusion conditions in LM26

Watch: Our two decades of technology development put commercial fusion within reach

Thanks to our in-house innovation, we prototype, test, and iterate rapidly to advance our technology. It also takes a village to bring a world-first fusion demonstration machine online within a year! Our wide network of industry experts and suppliers here in B.C., across Canada, and the globe play a critical role in our success. Teaming up with Canada’s top researchers from institutions across the country accelerates our technology development, builds Canada’s fusion expertise, and fosters the next generation of fusion researchers.

“There’s never been a more exciting time at General Fusion. After more than 20 years of technology development in Canada, we’re approaching breakthrough results with LM26, which will fast-track our path to providing commercial fusion power on the grid in the next decade. When LM26 begins compressing plasmas early in 2025, it will be a landmark moment for the company and the advancement of our practical MTF approach designed to scale for cost-efficient power plants.” — Dr. Michel Laberge, Founder and Chief Science Officer

Next up: It’s all systems go! Stay tuned.